Professor Ahmad Reza Rastkar BSc, MSc, PhD

Shahid Beheshti University

Professor of Surface Engineering

Address

Laser and Plasma Research Institute

Shahid Beheshti University

Velenjak

Tehran

1983969411

Iran

Ahmad Reza Rastkar is Professor of Surface Engineering and Leader of Plasma Processing Lab at the Laser and Plasma Research Institute in Shahid Beheshti University. He is a leading surface engineering expert in developing novel surface engineering techniques to improve the wear and corrosion resistance of Steels, Titanium alloys and Nickel alloys technologies as well as characterization of surface engineered components.

Professor Rastkar has published more than 60 papers in international journals and conferences together with 4 patents and 2 book chapters. During the past 20 years, he has successfully achieved several innovations in surface transformations and binding difficult to bond alloys such as titanium aluminides and superalloys. Another achievement is the development of the growth of vertically carbon nanotubes on different substrates that would be applicable in new challenging industries such as batteries and high emission cathodes in different high voltage and optical industries.

He is active in international surface engineering activities including invited lectures to major international conferences, organizations of national and international conferences and is an outstanding reviewer of academic journals.

PhD in Metallurgy & Materials (Surface Engineering and Tribology), Birmingham University, 2000

MSc in Material Engineering (Materials Selection and Manufacturing) Tribology, Shiraz University, Iran, 1991

BSc in Materials Engineering, Shiraz University, Iran, 1988

- plasma surface technology in BEng/MEng Materials Science and Engineering

- plasma laboratories in BEng/MEng Materials Science and Engineering

- manufacturing processesin BEng/MEng Materials Science and Engineering

- physical metallurgyin BEng/MEng Materials Science and Engineering

- heat treatmentin BEng/MEng Materials Science and Engineering

- welding in BEng/MEng Materials Science and Engineering

- non-destructive testing technologyin BEng/MEng Materials Science and Engineering

- advanced material analysis in BEng/MEng Materials Science and Engineering

- thermodynamics.of Materialsin BEng/MEng Materials Science and Engineering

|

Publications

lhttps://jtap.srbiau.ac.ir/article_22070.html

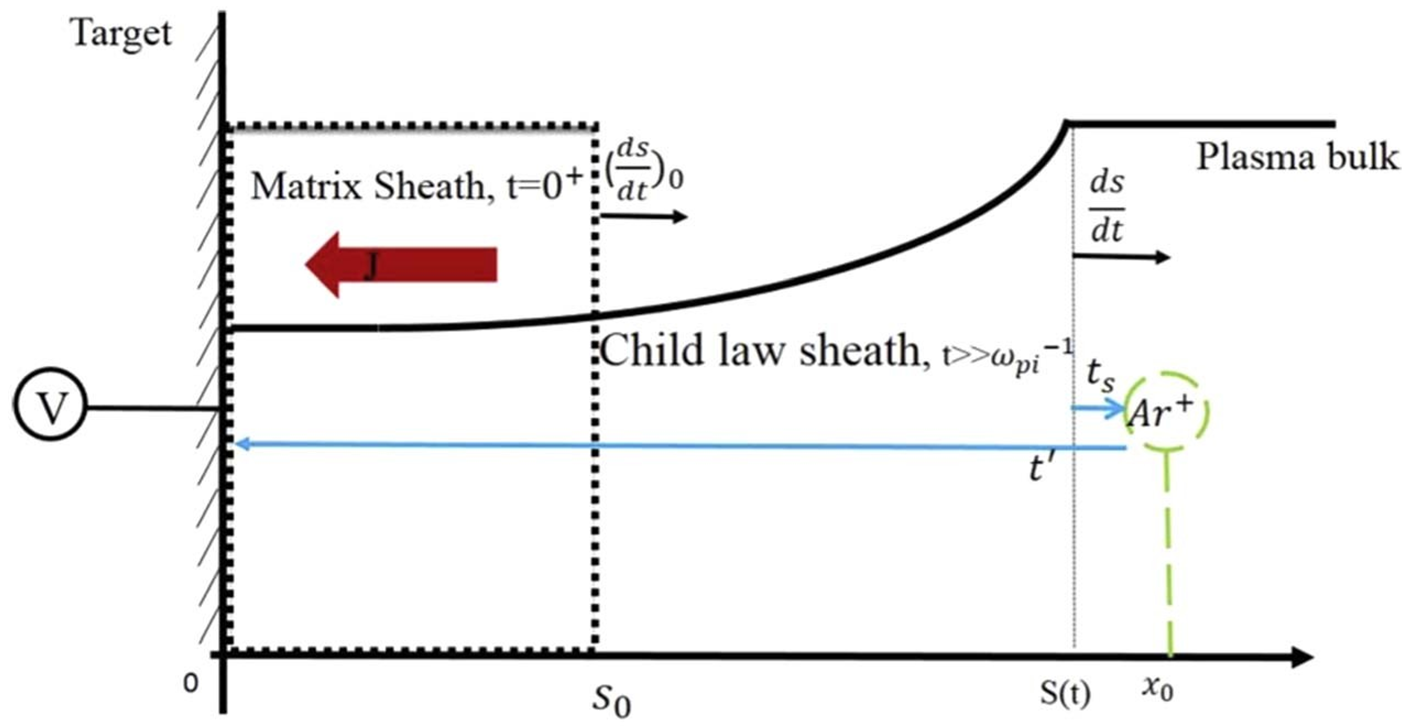

https://dr-rastkar.com/plasma-enhanced/

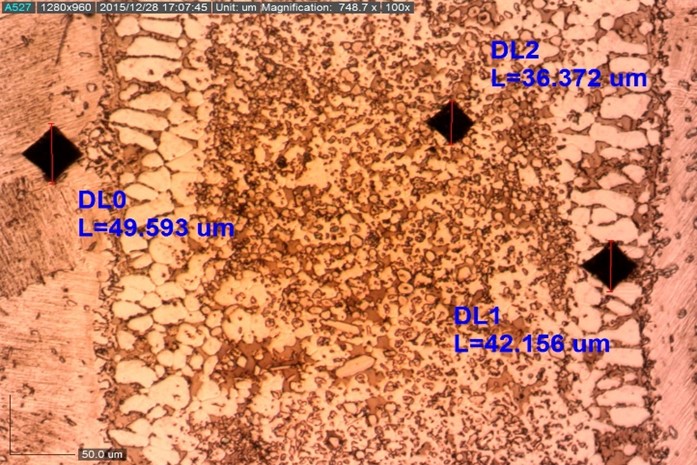

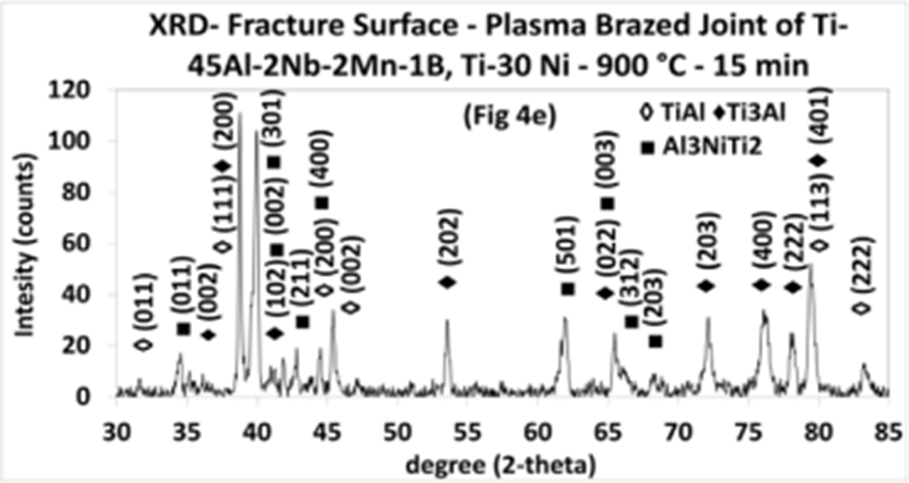

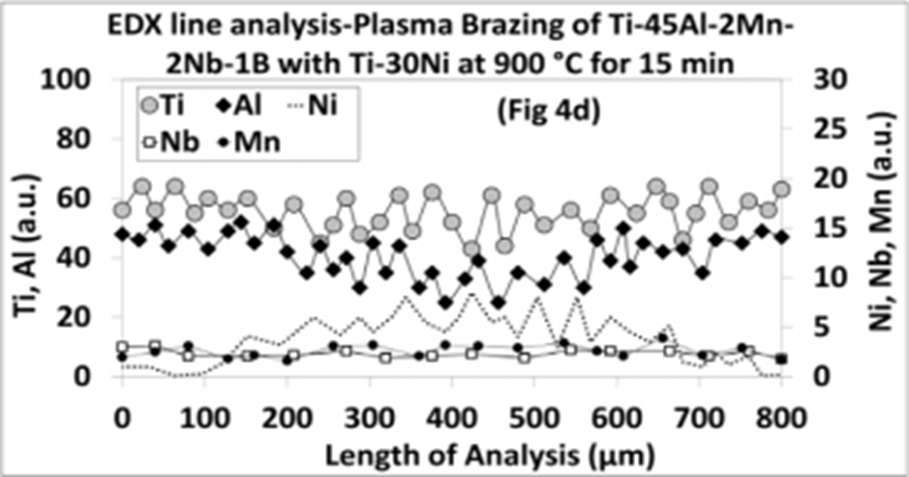

https://dr-rastkar.com/elementor-4544/

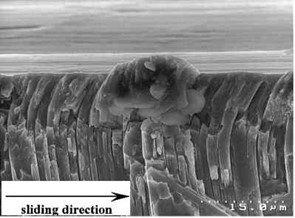

https://dr-rastkar.com/sliding-wear-titanium-aluminides/

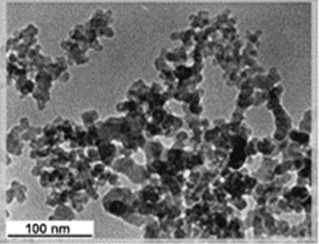

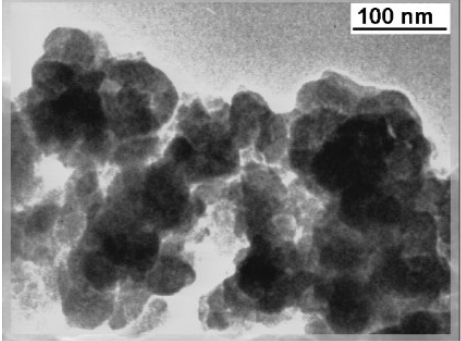

● A. R. Rastkar, “Plasma enhanced diffusion of Al-Si alloys on the surface of Ti-45Al-2Nb-2Mn-1B titanium aluminide”, Fifteenth International Conference on Plasma Surface Engineering-PSE 2016, Garmisch-Partenkirchen, Germany, September 12-16, 2016. ● A. R. Rastkar, “Plasma electrolytic process compete gaseous plasma nitriding of AISI 1045 steel”, Twelfth International Conference on Plasma Surface Engineering (PSE 2010), Garmisch-Partenkirchen, Germany, September 13-17, 2010. ● A. R. Rastkar, A. Kiani, B. Shokri, “Effect of pulsed plasma nitriding on Tribological performance of Ck45 steel”, 3 rd International Meeting on Developments in Materials, Processes and Applications of Emerging Technologies (MPA-2009), Manchester, UK, 21-23 July 2009. ● A. R. Rastkar, M. Kabir, M. Amirzadeh and M. Rahimipour, “Effect of pressure on the size of carbon nanoparticles deposited by pulsed plasma enhanced CVD of methane”, Eleventh International Conference on Plasma Surface Engineering-PSE, Garmisch-Partenkirchen, Germany, September 15-19, 2008. |

Projects to collaborate in Industrial Scale

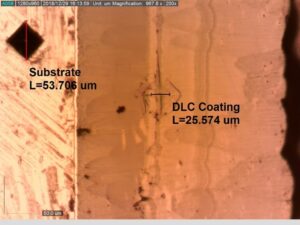

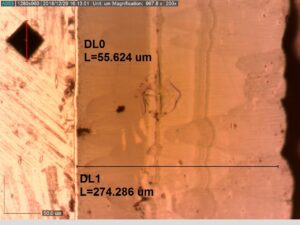

DLC coating on Ti-45Al-2Nb-2Mn can grow up to several tenth of microns by extending Plasma Carburizing to be used as a heat barrier, corrosion and wear resistant coating.

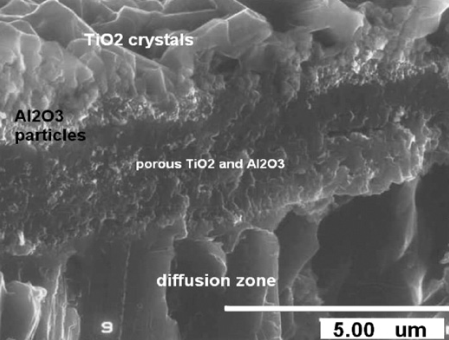

Plasma packed aluminized thick layers on Steels, Titanium Alloys or Aluminides and other Ni-Super Alloys enhance the life time of the corresponding components several times against wear and corrosion.

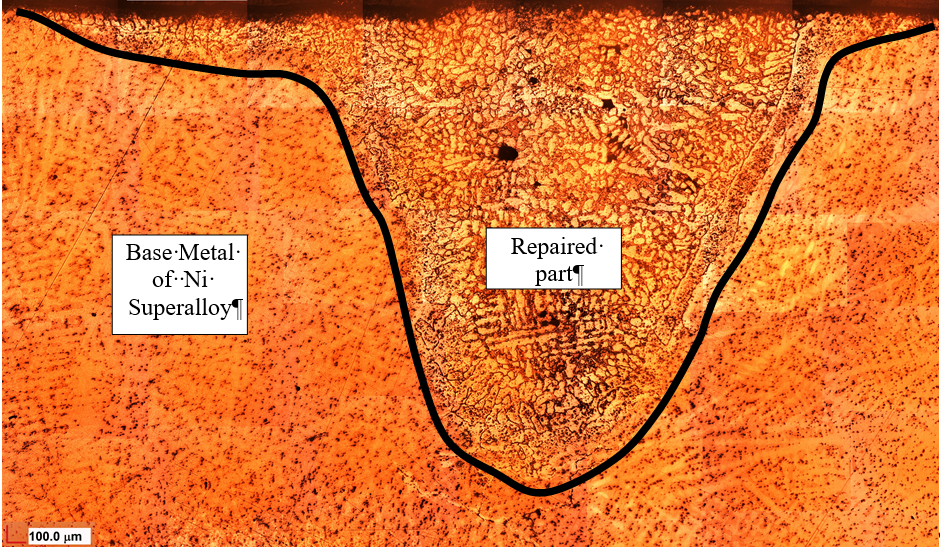

Repair of Ni-Superalloy with application of plasma arc on the powders of filler material added before plasma on the surface and processed in 10 min. No cracking, No nonconformity or adverse effect of welding passes.

Date and Signature

24.06.2023 A R Rastkar